Reverse Osmosis Plant (RO) In Bangalore

Quick Inspection Service Request

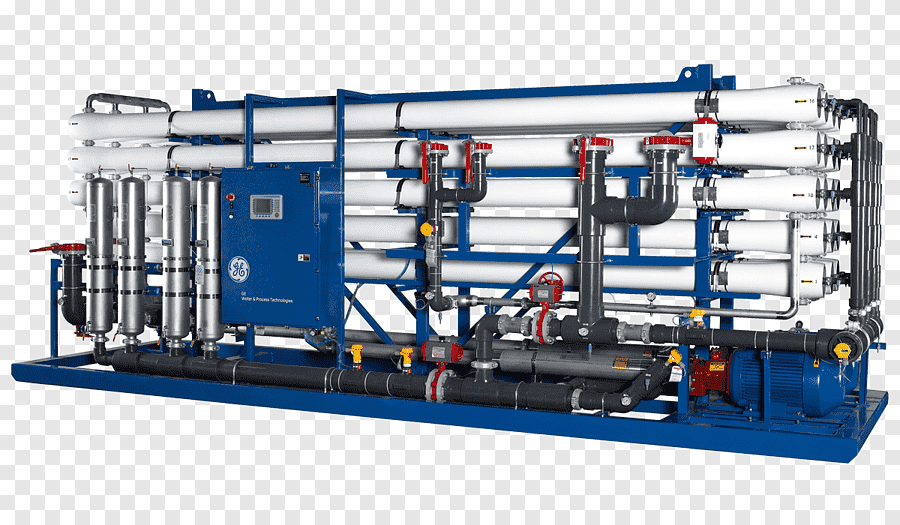

Reverse Osmosis Plant

Reverse Osmosis (RO) plants play a pivotal role in ensuring access to clean and potable water across various sectors, including industrial, commercial, and residential applications. However, to maintain optimal performance and longevity, these plants require regular maintenance and efficient operation. Annual Maintenance Contracts (AMC) and Operation & Maintenance (O&M) services are indispensable in this regard, offering comprehensive solutions to uphold the efficiency, reliability, and regulatory compliance of RO plants

Understanding Reverse Osmosis Plants

- Reverse osmosis is a water purification process that involves removing contaminants and impurities from water by using a semi-permeable membrane.

- Components: RO plants consist of various components, including membranes, pumps, pressure vessels, filters, instrumentation, and control systems.

- Applications: RO plants are utilized in diverse sectors, including municipal water treatment, industrial processes, food and beverage production, pharmaceutical manufacturing, and residential water purification.

Importance of AMC & O&M Services and Components

- Ensuring Operational Efficiency: Regular maintenance and operation activities optimize the performance of RO plants, ensuring consistent water quality and quantity.

- Longevity and Sustainability: Proper maintenance and operation practices prolong the lifespan of equipment and components, reducing the need for premature replacements and minimizing environmental impact.

- Compliance and Quality Assurance: AMC and O&M services facilitate adherence to regulatory standards and guidelines governing water quality, safety, and environmental protection.

- Cost Efficiency: By preventing unexpected breakdowns, minimizing downtime, and optimizing energy and resource utilization, these services contribute to overall cost savings and operational efficiency.

Components

Routine Inspections:

- Visual inspection of equipment, including membranes, pumps, valves, and piping systems, to identify signs of wear, corrosion, or leaks.

- Performance monitoring to assess key parameters such as flow rates, pressure levels, temperature, and water quality indicators. b. Preventive Maintenance:

- Cleaning and sanitation of membranes, filters, and other components to prevent fouling, scaling, and biological growth.

- Calibration and testing of instrumentation and control systems to ensure accurate measurement and control of process variables.

- Replacement of consumable parts, such as seals, O-rings, filter cartridges, and membrane elements, based on manufacturer recommendations and operational requirements. c. Operational Support:

- Continuous monitoring of plant performance and process parameters to identify deviations and take corrective actions promptly.

- Optimization of operating parameters, including feed flow rates, pressure, recovery rates, and chemical dosing, to maximize efficiency and minimize energy consumption.

- Troubleshooting and fault diagnosis to address operational issues and malfunctions in a timely manner, minimizing downtime and production losses. d. Training and Capacity Building:

- Training programs for plant operators and maintenance personnel to enhance their knowledge and skills in RO plant operation, maintenance, and troubleshooting.

- Knowledge transfer and documentation of best practices, standard operating procedures (SOPs), and lessons learned to ensure continuity and sustainability of operations. e. Performance Monitoring and Reporting:

- Regular monitoring of key performance indicators (KPIs) and water quality parameters, including pH, conductivity, total dissolved solids (TDS), and microbial counts.

- Generation of comprehensive reports and performance dashboards to track trends, identify areas for improvement, and demonstrate compliance with regulatory requirements.

Site Inspection

Schedule An Appointment

Benefits of RO Plant AMC & O&M Services From ASWS in Bangalore

- Reliability and Resilience: AMC and O&M services enhance the reliability and resilience of RO plants, ensuring uninterrupted operation and consistent water quality.

- Regulatory Compliance: By implementing proactive maintenance and operation practices, these services help RO plants meet regulatory standards and guidelines for water quality, safety, and environmental protection.

- Cost Savings: By preventing costly breakdowns, optimizing energy and resource utilization, and prolonging equipment lifespan, AMC and O&M services contribute to overall cost savings and operational efficiency.

- Expertise and Support: AMC and O&M service providers bring specialized knowledge, experience, and technical expertise to support the efficient operation and maintenance of RO plants, enabling plant owners and operators to focus on their core business activities.

- Sustainability: By promoting efficient resource utilization, minimizing environmental impact, and extending equipment lifespan, these services contribute to the sustainability and environmental responsibility of RO plant operations.

Additional Sewage Treatment Plant Services

We Also Offer